Parameter

Parameter

Parameter.

01

Professional LCD molding resin: Optimize the formation of LCD low light source and printing efficiency is higher than the market compatible DLP / LCD / SLA resin. The resin is only designed for the LCD model of the resin, not recommended DLP or SLA machine.

02

High-speed solidify: This resin ensures the strength of molded parts and not excessive shrinkage, but also improve print speed, shorten the curing time and enhance the printing efficiency of LCD machines as much as possible.

03

Strong adhesion of the model and easy to detach after forming: Not only high success rate of printing and precision, but also to minimize resin release force and adhesion, so that the model attached to the forming platform can easily shovel and low viscosity makes it easier to clean the machine and model.

04

The material is rigid and tough: Strong material in the shovel model can easily lead to the model fragmentation, but too flexible material will be prone to the details of the print tensile deformation or fracture, which will affect the molding accuracy and aesthetics.

05

Model’s performance is stable: The resin is stable under different climatic conditions and is also easy to store, overcoming the shortcomings of other resins easily damp softening and environmental corrosion

06

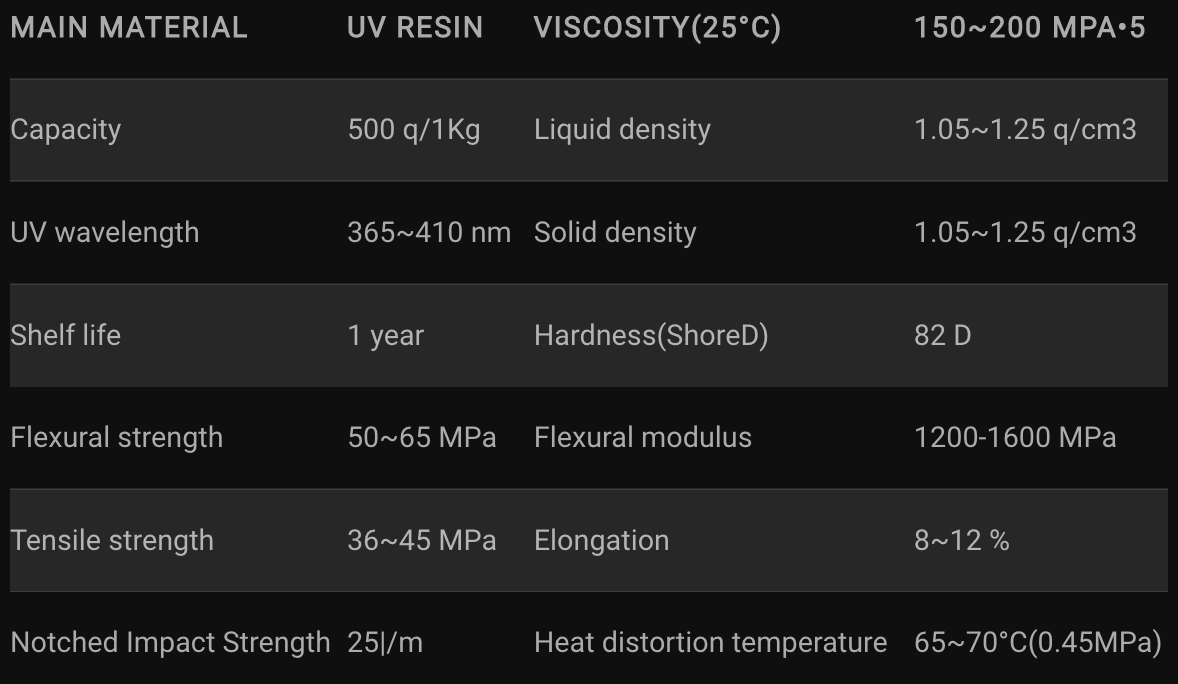

Parameter information:

- Main material: resin monomer & photo initiator

- Exposure parameters: Bottom exposure time(s) 20-60s, normal exposure time(s) 5-15s.

| Main material | UV Resin | Viscosity(25°C) | 150~200 mPa•5 |

|---|---|---|---|

| Capacity | 500 q/1Kg | Liquid density | 1.05~1.25 q/cm3 |

| UV wavelength | 365~410 nm | Solid density | 1.05~1.25 q/cm3 |

| Shelf life | 1 year | Hardness(ShoreD) | 82 D |

| Flexural strength | 50~65 MPa | Flexural modulus | 1200-1600 MPa |

| Tensile strength | 36~45 MPa | Elongation | 8~12 % |

| Notched Impact Strength | 25|/m | Heat distortion temperature | 65~70°C(0.45MPa) |

Precautions

-

- Shake well before use, prohibiting the use of resin in places where there is a lot of sunlight.

- Wear gloves before use to avoid direct contact with the skin and keep the room ventilated.

- Inadvertent contact, as soon as possible to use a lot of water rinse. If you feel unwell, seek timely medical attention.

- Printed models need to use high-concentration alcohol to clean about the 30S (recommended concentration of 95% or more, the higher the better).

- Do not pour the resin in the resin vat into the unused resin, and do not leave the resin in the resin vat for a long time without use to avoid resin pollution affecting the printing effect(long time without the resin can be introduced into airtight containers or sealed with plastic wrap shading save).

- Resin has a shelf life of up to 18 months.

-

Storage method:

- Keep away from light seals at room temperature (sunshine contains a lot of UV light, will solidify photosensitive resin. After testing, the light is not affected as long as it is not UV light).

- It is recommended to save at 15 ℃ -35 ℃ ambient temperature, the lower the temperature, the higher the viscosity of the resin. Sealed storage, excessive dust or moisture can affect print quality. Sunshine contains a lot of UV light, will solidify photosensitive resin.

Precautions.

-

- Shake well before use, prohibiting the use of resin in places where there is a lot of sunlight.

- Wear gloves before use to avoid direct contact with the skin and keep the room ventilated.

- Inadvertent contact, as soon as possible to use a lot of water rinse. If you feel unwell, seek timely medical attention.

- Printed models need to use high-concentration alcohol to clean about the 30S (recommended concentration of 95% or more, the higher the better).

- Do not pour the resin in the resin vat into the unused resin, and do not leave the resin in the resin vat for a long time without use to avoid resin pollution affecting the printing effect(long time without the resin can be introduced into airtight containers or sealed with plastic wrap shading save).

- Resin has a shelf life of up to 18 months.

-

Storage method:

- Keep away from light seals at room temperature (sunshine contains a lot of UV light, will solidify photosensitive resin. After testing, the light is not affected as long as it is not UV light).

- It is recommended to save at 15 ℃ -35 ℃ ambient temperature, the lower the temperature, the higher the viscosity of the resin. Sealed storage, excessive dust or moisture can affect print quality. Sunshine contains a lot of UV light, will solidify photosensitive resin.

3D

You may also like.

You may also

like.