Anycubic Standard Resin+ 1KG

35,00 €

Our Standard UV Resin delivers great performances such as high printing success rate, good adhesion, high level of detail and high printing accuracy. Its performances also includes a high hardness and toughness, a great fluidity, low smell, easy cleaning and other aspects. Based on these good qualities of the Classic Resin that Anycubic developed this Anycubic Standard Resin +.

Classic Formula

Compatible with DLP

Extended Shelf Life

Anycubic Standard Resin+ 1KG

35,00 €

Our Standard UV Resin delivers great performances such as high printing success rate, good adhesion, high level of detail and high printing accuracy. Its performances also includes a high hardness and toughness, a great fluidity, low smell, easy cleaning and other aspects. Based on these good qualities of the Classic Resin that Anycubic developed this Anycubic Standard Resin +.

Classic Formula

Compatible with DLP

Extended Shelf Life

Parameter

Parameter

Parameter.

01

Upgraded Classic Resin Formula

Its performances includes a high hardness and toughness,

a great fluidity, low smell, easy cleaning and other aspects.

Based on these good qualities of the Classic.

02

Accuracy and Toughness Upgrades

Anycubic Standard Resin + gathers all the advantages

of Anycubic UV resin, and focuses on optimizing the printing

accuracy and the toughness so that your prints will not only

be rich in details, but also keep resistant when falling.

03

Accuracy

Molding accuracy: the range has been increased from +0.2mm to +0.1mm

04

Compatible with Most LCD and DLP Printers

As a leading manufacturer and pioneer for global desktop 3D

printers, Anycubic gives consideration to the compatibility to

LCD and DP while developing the Standard Resin +, making it

compatible for most printers of both types while developing the

StandardResin +, making it compatible for most printers of both types.

05

18-Month Expiration Date

Most resin for 3D printing have a expiration date of only

one year. With upgrades to the formula and packaging, Anycubic

Standard Resin + extends its expiration date to 18 months.

05

Low Odor & Less Worry

Benefiting the upgraded formulation, Anycubic Standard

Resin+release a much lighter smell during printing than

basic resin and will have less impact on your daily life.

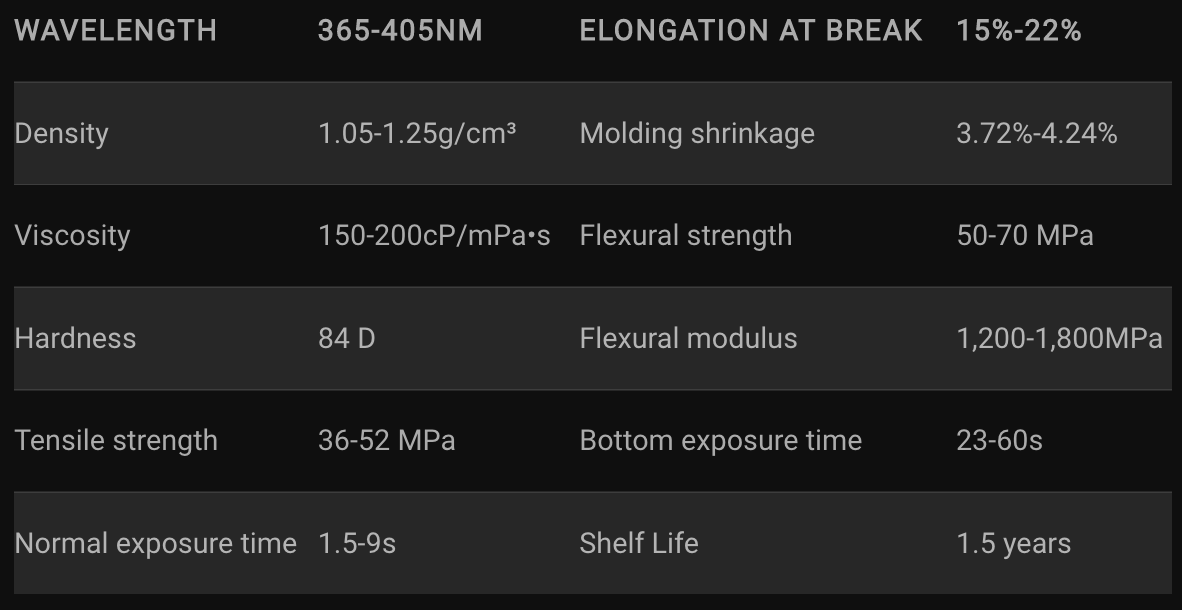

| Wavelength | 365-405nm | Elongation at break | 15%-22% |

|---|---|---|---|

| Density | 1.05-1.25g/cm³ | Molding shrinkage | 3.72%-4.24% |

| Viscosity | 150-200cP/mPa•s | Flexural strength | 50-70 MPa |

| Hardness | 84 D | Flexural modulus | 1,200-1,800MPa |

| Tensile strength | 36-52 MPa | Bottom exposure time | 23-60s |

| Normal exposure time | 1.5-9s | Shelf Life | 1.5 years |

Precautions

-

- Before use: Shake the liquid resin before use; Clean the resin tank and the molding platform to keep the bottom of the resin tank in light transmission.

- When using: Unscrew the cap and add it to the resin tank according to the equipment requirements; Select the correct print parameters and settings for printing.

- After use: After printing, please use the matching tools for post-processing, including blade, diagonal pliers, tweezers, containers, gloves; ethanol (>95%), lactate or isopropyl alcool cleaning solution;

- Post-processing steps:

A. Remove the printed model from the molding platform with a blade;

B. Submerge the model in the cleaning solution, rinsed or ultrasonically washed, then taken out and drained; ANYCUBIC Wash and Cure machines are suggested to ensure better effect.

C. Proper processing, such as removing support, polishing, coloring, etc.

-

- The ideal condition for storing uncured resin is a cool, dark place at room temperature and protect from light to avoid high temperature or sunlight.

- Suggested operating temperature is 18-35°C, and a low temperature may affect the printing effect, thus, the resin can be properly preheated before use (not more than 60°C).

- If the resin pigment settles, it can be used after stirring or shaking.

- To ensure the ideal performance of the curable material, it is necessary to control the intensity and time of the light source after curing, so it is recommended that: (1) The intensity of mercury lamp or LED light source is 5-10mW/m2, and the duration is no more than 1 hour (self-regulation); (2) The exposure time in the sun (summer) is around 1 hour; (3) Proximity or long-term exposure under strong light sources such as high-power high-pressure mercury lamps is prohibited. (4) It is recommended to print in a dark room or be covered with a lid while printing as resin is a photosensitive material.

- PS: Material properties will vary depending on the molding equipment, post-cure method and testing equipment. For safety information, please refer to the MSDS of this product. If you encounter any problems during use, please feel free to contact us.

Precautions.

-

- Before use: Shake the liquid resin before use; Clean the resin tank and the molding platform to keep the bottom of the resin tank in light transmission.

- When using: Unscrew the cap and add it to the resin tank according to the equipment requirements; Select the correct print parameters and settings for printing.

- After use: After printing, please use the matching tools for post-processing, including blade, diagonal pliers, tweezers, containers, gloves; ethanol (>95%), lactate or isopropyl alcool cleaning solution;

- Post-processing steps:

A. Remove the printed model from the molding platform with a blade;

B. Submerge the model in the cleaning solution, rinsed or ultrasonically washed, then taken out and drained; ANYCUBIC Wash and Cure machines are suggested to ensure better effect.

C. Proper processing, such as removing support, polishing, coloring, etc.

-

- Keep sealed and away from light at room temperature. Avoid heat or sunlight.

- Recommended temperature: 18-35°C. The printing effect may be affected if the temperature is too low. The resin can be preheated properly (not more than 60°C) before use.

- In case of settlement of resin pigment, please stirring or shaking well before use.

- In order to ensure the desired properties of cured materials, the intensity and time of light source during post-curing should be controlled. Therefore, it is suggested that:

(1) The intensity of mercury lamp or LED light source is 5-10MW /m2, and the duration shall not exceed 1 hour (self-regulation);

(2) The duration of sun exposure (summer) should be controlled at about 1 hour;

(3) Close or long-term exposure under strong light sources such as high-power high-pressure mercury lamp is prohibited;

(4) It is recommended to print in a dark room, or cover when printing. - Material performance may vary and depend on individual machine processing and post-curing. Please refer to the PRODUCT MSDS for safety information. Please feel free to contact us if there are any problems.

3D

You may also like.

You may also

like.