Anycubic Plant-based UV Resin + 1KG

69,99 €

An upgrade to the resilience of the plant-based

resin brings both good toughness and strength to the models, making them easier to shape and shockproof.

Degraded Performance

Eco-Friendly

Light Odor

Accurate and Stable

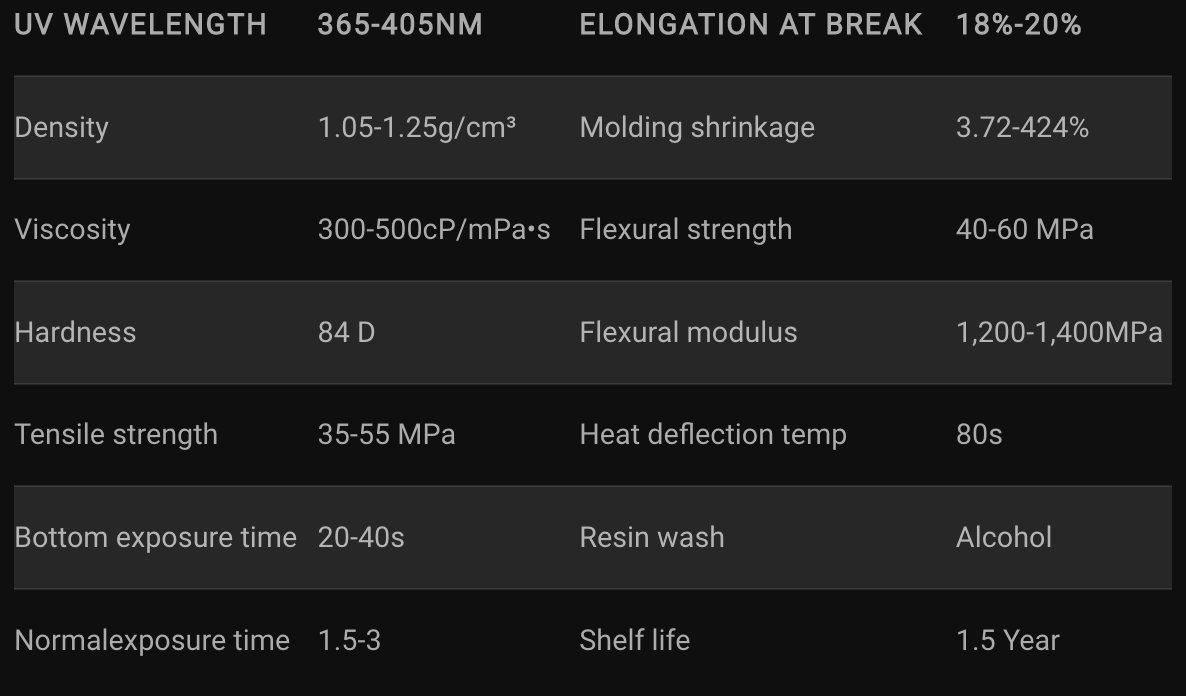

Parameter

Parameter

Parameter.

01

Balance Between & Toughness and Resilience

An upgrade to the resilience of the plant-based

resin brings both good toughness and strength to the models, making them easier to shape and shockproof.

02

Balanced Performance

Plant-based UV Resin + Mechanical Property Comparison

03

Recommendation Index

Improved toughness, more resistant to bending.

04

Stable High Performance and Delicate

A low shrinkage rate makes less deformation to the

models when building. The smooth and fine details of

the finished miniatures highlight the premium quality.

05

Eco-friendly & Light odor

Soy extract formula, BPA-free, benzene toxin-free, and

irritating VOCs volatile-free. Low odor and safe to use.

06

Widely Compatible

Suited to most of the LCD 3D printers in the market.

Better results in use with Anycubic LCD 3D printers.

| UV wavelength | 365-405nm | Elongation at break | 18%-20% |

|---|---|---|---|

| Density | 1.05-1.25g/cm³ | Molding shrinkage | 3.72-424% |

| Viscosity | 300-500cP/mPa•s | Flexural strength | 40-60 MPa |

| Hardness | 84 D | Flexural modulus | 1,200-1,400MPa |

| Tensile strength | 35-55 MPa | Heat deflection temp | 80s |

| Bottom exposure time | 20-40s | Resin wash | Alcohol |

| Normalexposure time | 1.5-3 | Shelf life | 1.5 Year |

Precautions

-

- Before use: Shake the resin well before use; Clean the resin tank and platform, keep the bottom of the resin tank highly transparent.

- When using: Unscrew the cap and add it to the resin tank according to requirements; Select the correct print Settings to print.

- After use: After printing, use supporting tools for post-processing, including spatula; diagonal pliers, tweezers, containers, and gloves, Ethanol (≥95%); lactate or isopropyl alcool cleaning liquid.

- Post-processing steps:

A. Remove the finished print from the platform with a spatula;

B. Cleaning and curing. - Using ANYCUBIC wash&cure machine better effec;

-

- Keep sealed and away from light at room temperature. Avoid heat or sunlight.

- Recommended temperature: 18-35°C. The printing effect may be affected if the temperature is too low. The resin can be preheated properly (not more than 60°C) before use.

- In case of settlement of resin pigment, please stirring or shaking well before use.

- In order to ensure the desired properties of cured materials, the intensity and time of light source during post-curing should be controlled. Therefore, it is suggested that:

(1) The intensity of mercury lamp or LED light source is 5-10MW /m2, and the duration shall not exceed 1 hour (self-regulation);

(2) The duration of sun exposure (summer) should be controlled at about 1 hour:

(3) Close or long-term exposure under strong light sources such as high-power high-pressure mercury lamp is prohibited;

(4) It is recommended to print in a dark room, or cover when printing. - Material performance may vary and depend on individual machine processing and post-curing. Please refer to the PRODUCT MSDS for safety information. Please feel free to contact us if there are any problems.

Precautions.

-

- Before use: Shake the resin well before use; Clean the resin tank and platform, keep the bottom of the resin tank highly transparent.

- When using: Unscrew the cap and add it to the resin tank according to requirements; Select the correct print Settings to print.

- After use: After printing, use supporting tools for post-processing, including spatula; diagonal pliers, tweezers, containers, and gloves, Ethanol (≥95%); lactate or isopropyl alcool cleaning liquid.

- Post-processing steps:

A. Remove the finished print from the platform with a spatula;

B. Cleaning and curing. - Using ANYCUBIC wash&cure machine better effec;

-

- Keep sealed and away from light at room temperature. Avoid heat or sunlight.

- Recommended temperature: 18-35°C. The printing effect may be affected if the temperature is too low. The resin can be preheated properly (not more than 60°C) before use.

- In case of settlement of resin pigment, please stirring or shaking well before use.

- In order to ensure the desired properties of cured materials, the intensity and time of light source during post-curing should be controlled. Therefore, it is suggested that:

(1) The intensity of mercury lamp or LED light source is 5-10MW /m2, and the duration shall not exceed 1 hour (self-regulation);

(2) The duration of sun exposure (summer) should be controlled at about 1 hour:

(3) Close or long-term exposure under strong light sources such as high-power high-pressure mercury lamp is prohibited;

(4) It is recommended to print in a dark room, or cover when printing. - Material performance may vary and depend on individual machine processing and post-curing. Please refer to the PRODUCT MSDS for safety information. Please feel free to contact us if there are any problems.

3D

You may also like.

You may also

like.