Anycubic Flexible Tough Resin 1KG

- Balancing softness with strength, Anycubic Flexible Tough Resin can withstand bending, flexing, and compression. It shows good strength and elongation and the ability to resist cracking while drilling holes.

-

Parts printed with Anycubic Flexible Tough Resin are crash-proof and show high impact strength. Besides, it can withstand high impact and other high-strength mechanical pressure.

-

It can provide high accuracy, smooth surface, clear print details and low shrinkage rate advantages for model printing.

-

Applicable for most LCD 3D printers and optimized for 3D printing wavelengths between 365nm – 405nm, better effect with ANYCUBIC LCD 3D printers.

- Applicable for all kinds of models, shells and parts with rigid requirements, such as industrial spare parts, building models, DIY, maker design, daily design and other high-strength model production.

Anycubic Flexible Tough Resin 1KG

- Balancing softness with strength, Anycubic Flexible Tough Resin can withstand bending, flexing, and compression. It shows good strength and elongation and the ability to resist cracking while drilling holes.

-

Parts printed with Anycubic Flexible Tough Resin are crash-proof and show high impact strength. Besides, it can withstand high impact and other high-strength mechanical pressure.

-

It can provide high accuracy, smooth surface, clear print details and low shrinkage rate advantages for model printing.

-

Applicable for most LCD 3D printers and optimized for 3D printing wavelengths between 365nm – 405nm, better effect with ANYCUBIC LCD 3D printers.

- Applicable for all kinds of models, shells and parts with rigid requirements, such as industrial spare parts, building models, DIY, maker design, daily design and other high-strength model production.

Parameter

Parameter

Parameter.

High Toughness

Not Easy to Break

High Rigidity and

High Impact Strength

High precision

Low shrinkage

Wide Compatibility

Industry Applications

Optional Colors

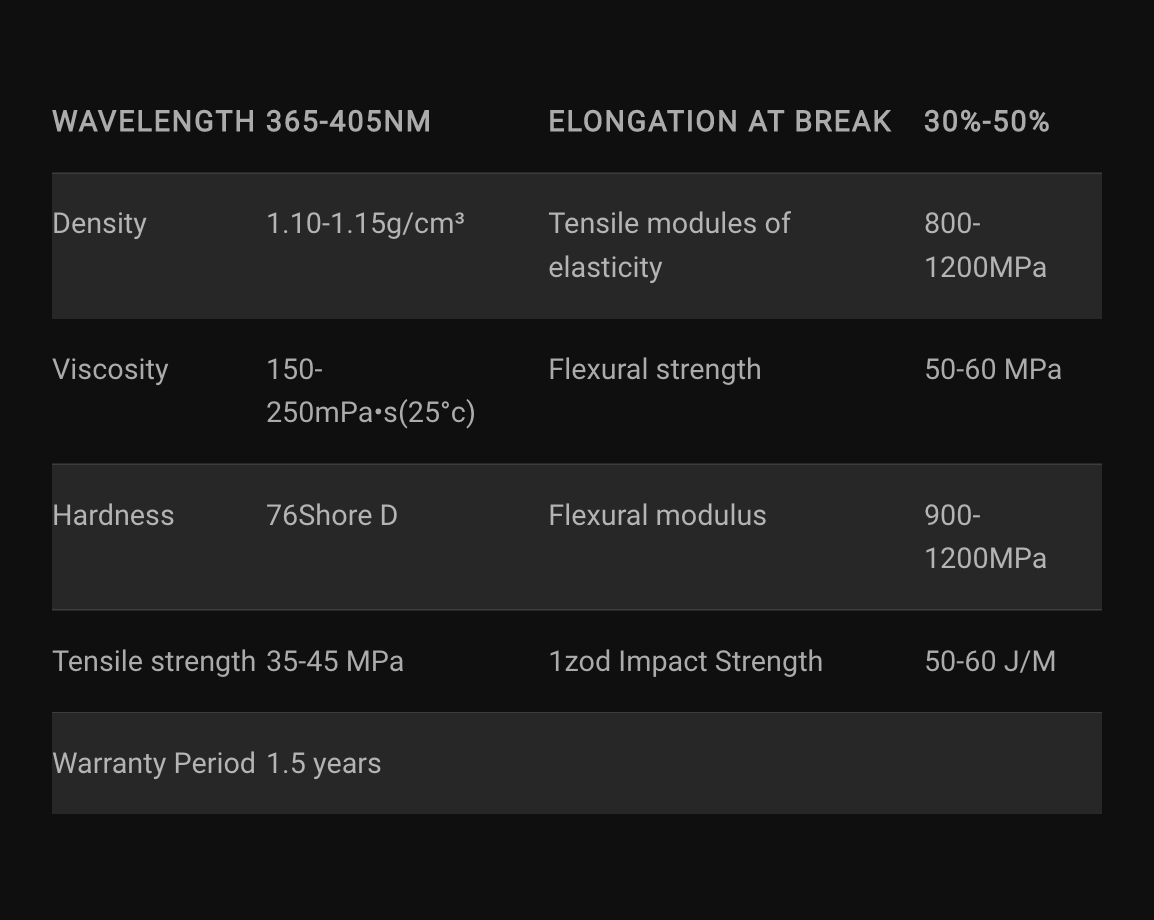

| Wavelength | 365-405nm | Elongation at break | 30%-50% |

|---|---|---|---|

| Density | 1.10-1.15g/cm³ | Tensile modules of elasticity | 800-1200MPa |

| Viscosity | 150-250mPa•s(25°c) | Flexural strength | 50-60 MPa |

| Hardness | 76Shore D | Flexural modulus | 900-1200MPa |

| Tensile strength | 35-45 MPa | 1zod Impact Strength | 50-60 J/M |

| Warranty Period | 1.5 years |

Precautions

-

- Before use: Shake the liquid resin before use; Clean the resin tank and the molding platform to keep the bottom of the resin tank in light transmission.

- When using: Unscrew the cap and add it to the resin tank according to the equipment requirements; Select the correct print parameters and settings for printing.

- After use: After printing, please use the matching tools for post-processing, including blade, diagonal pliers, tweezers, containers, gloves; ethanol (>95%), lactate or isopropyl alcool cleaning solution;

- Post-processing steps:

A. Remove the printed model from the molding platform with a blade;

B. Submerge the model in the cleaning solution, rinsed or ultrasonically washed, then taken out and drained; ANYCUBIC Wash and Cure machines are suggested to ensure better effect.

C. Proper processing, such as removing support, polishing, coloring, etc.

-

- The ideal condition for storing uncured resin is a cool, dark place at room temperature and protect from light to avoid high temperature or sunlight.

- Suggested operating temperature is 18-35°C, and a low temperature may affect the printing effect, thus, the resin can be properly preheated before use (not more than 60°C).

- If the resin pigment settles, it can be used after stirring or shaking.

- To ensure the ideal performance of the curable material, it is necessary to control the intensity and time of the light source after curing, so it is recommended that: (1) The intensity of mercury lamp or LED light source is 5-10mW/m2, and the duration is no more than 1 hour (self-regulation); (2) The exposure time in the sun (summer) is around 1 hour; (3) Proximity or long-term exposure under strong light sources such as high-power high-pressure mercury lamps is prohibited. (4) It is recommended to print in a dark room or be covered with a lid while printing as resin is a photosensitive material.

- PS: Material properties will vary depending on the molding equipment, post-cure method and testing equipment. For safety information, please refer to the MSDS of this product. If you encounter any problems during use, please feel free to contact us.

-

- Before use: Shake the liquid resin before use; Clean the resin tank and the molding platform to keep the bottom of the resin tank in light transmission.

- When using: Unscrew the cap and add it to the resin tank according to the equipment requirements; Select the correct print parameters and settings for printing.

- After use: After printing, please use the matching tools for post-processing, including blade, diagonal pliers, tweezers, containers, gloves; ethanol (>95%), lactate or isopropyl alcool cleaning solution;

- Post-processing steps:

A. Remove the printed model from the molding platform with a blade;

B. Submerge the model in the cleaning solution, rinsed or ultrasonically washed, then taken out and drained; ANYCUBIC Wash and Cure machines are suggested to ensure better effect.

C. Proper processing, such as removing support, polishing, coloring, etc.

-

- The ideal condition for storing uncured resin is a cool, dark place at room temperature and protect from light to avoid high temperature or sunlight.

- Suggested operating temperature is 18-35°C, and a low temperature may affect the printing effect, thus, the resin can be properly preheated before use (not more than 60°C).

- If the resin pigment settles, it can be used after stirring or shaking.

- To ensure the ideal performance of the curable material, it is necessary to control the intensity and time of the light source after curing, so it is recommended that: (1) The intensity of mercury lamp or LED light source is 5-10mW/m2, and the duration is no more than 1 hour (self-regulation); (2) The exposure time in the sun (summer) is around 1 hour; (3) Proximity or long-term exposure under strong light sources such as high-power high-pressure mercury lamps is prohibited. (4) It is recommended to print in a dark room or be covered with a lid while printing as resin is a photosensitive material.

- PS: Material properties will vary depending on the molding equipment, post-cure method and testing equipment. For safety information, please refer to the MSDS of this product. If you encounter any problems during use, please feel free to contact us.