Anycubic ABS-Like Resin+ 1KG

39,00 €

Adding PUA (polyurethane acrylate) to the formula gives the resin excellent tensile and bending strength as well as hardness and toughness.

Strong Formula

High Precision

Long Lasting

Parameter

Parameter

Parameter.

01

Excellent Tensile & Bending Strength

Adding PUA (polyurethane acrylate) to the formula

gives the resin excellent tensile and bending

strength as well as hardness and toughness.

02

Performance

Easy to clean. Hardness. Low odor. Easy to cure. Bending resistance. Accuracy. Speed. High temperature resistence.

03

Better Fluidity Improves the High Precision

Improved fluidity significantly reduces curing

time, and ensures a printing accuracy of ‡0.1mm.

04

Wide Compatibility

Especially designed to be compatible with various LCD and DLP 3D printers.

05

Long Conservation Period

The conservation period of the Anycubic ABS-Like Resin+ is 18 months, which is longer than other resins on the market.

06

Large Choice of Color

Multiple colors avaible. Long lasting shine.

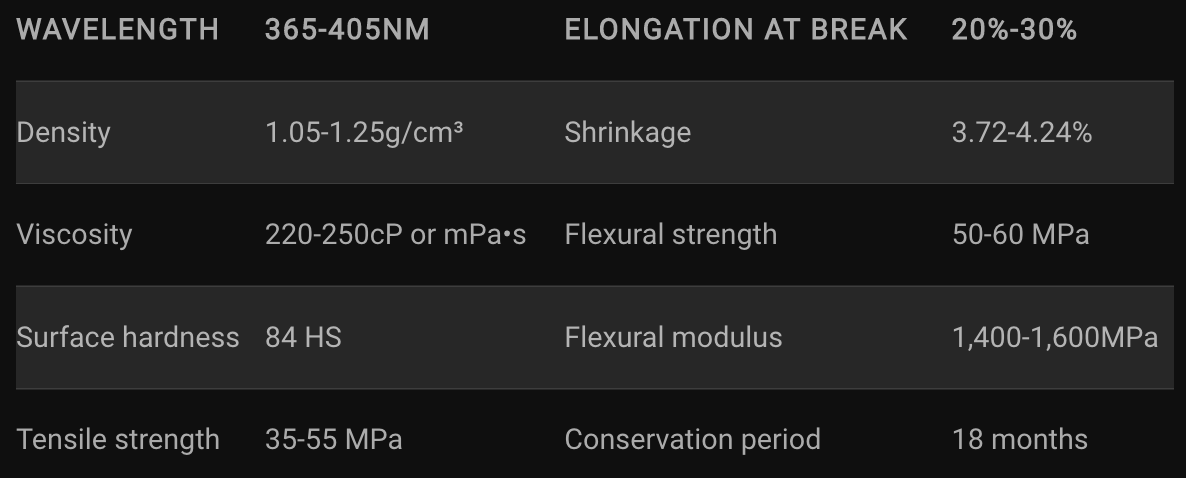

| Wavelength | 365-405nm | Elongation at break | 20%-30% |

|---|---|---|---|

| Density | 1.05-1.25g/cm³ | Shrinkage | 3.72-4.24% |

| Viscosity | 220-250cP or mPa•s | Flexural strength | 50-60 MPa |

| Surface hardness | 84 HS | Flexural modulus | 1,400-1,600MPa |

| Tensile strength | 35-55 MPa | Conservation period | 18 months |

Precautions

-

- (1) Before use: Shake the resin well before use; Clean the resin vat and the building plate, and make sure the bottom of the resin vat is transparent.

- (2) When operating: Unscrew the cap, pour the resin into the vat according to the quantity needed, and set the printer properly.

- (3) After use: After printing, please use the following tools for post-processing: scraper, diagonal cutting pliers, tweezers, containers, gloves, Ethanol (≥95%), lactate or isopropyl alcool cleaning solution.

- (4) Post-processing:

A. Remove the finished print from the build plate with a scraper;

B. Clean and cure. We recommend to use the Anycubic Wash & Cure Machine for better results.

C. Remove supports, polish and paint, etc…

-

- Store at room temperature, keep sealed and away from light. Avoid heat and direct sunlight.

- Suggested strage temperature: 18-35°C. Low temperatures might affect the printing results. The resin can be preheated (no more than 60°C) before use.

- In case of resin pigment settlement, please stir or shake well before use.

- To ensure the best properties of the cured models, remember to control the intensity and the exposure time of the light source.

(1) The intensity of lamps or LED light source should not exceed 5-10mW/m2 and the exposition time should not exceed 1 hour (self-regulation);

(2) Sunlight exposure time (summer) should not exceed 1 hour;

(3) Close range exposure or prolonged exposure under strong light sources such as high power and high voltage lamp is proibited.

(4) It is recommended to print in a dark room or put on the cover when printing. - Material performance may vary and is subject to the machine used and post-curing technique. Please refer to the product MSDS for safety information. Should you have any problems or questions, please feel free to contact us.

Precautions.

-

- (1) Before use: Shake the resin well before use; Clean the resin vat and the building plate, and make sure the bottom of the resin vat is transparent.

- (2) When operating: Unscrew the cap, pour the resin into the vat according to the quantity needed, and set the printer properly.

- (3) After use: After printing, please use the following tools for post-processing: scraper, diagonal cutting pliers, tweezers, containers, gloves, Ethanol (≥95%), lactate or isopropyl alcool cleaning solution.

- (4) Post-processing:

A. Remove the finished print from the build plate with a scraper;

B. Clean and cure. We recommend to use the Anycubic Wash & Cure Machine for better results.

C. Remove supports, polish and paint, etc…

-

- Store at room temperature, keep sealed and away from light. Avoid heat and direct sunlight.

- Suggested strage temperature: 18-35°C. Low temperatures might affect the printing results. The resin can be preheated (no more than 60°C) before use.

- In case of resin pigment settlement, please stir or shake well before use.

- To ensure the best properties of the cured models, remember to control the intensity and the exposure time of the light source.

(1) The intensity of lamps or LED light source should not exceed 5-10mW/m2 and the exposition time should not exceed 1 hour (self-regulation);

(2) Sunlight exposure time (summer) should not exceed 1 hour;

(3) Close range exposure or prolonged exposure under strong light sources such as high power and high voltage lamp is proibited.

(4) It is recommended to print in a dark room or put on the cover when printing. - Material performance may vary and is subject to the machine used and post-curing technique. Please refer to the product MSDS for safety information. Should you have any problems or questions, please feel free to contact us.

3D

You may also like.

You may also

like.