1.75mm Silk PLA 3D Printer Filament 1KG

26,00 € – 390,00 €

Silk PLAs normally produce impressive prints that are shiny and seemingly a bit translucent, giving them both the feel and look of being covered in silk. With this kind of filament, there’s no need to paint, as the natural appearance is already quite dazzling.

1.75mm Silk PLA 3D Printer Filament 1KG

26,00 € – 390,00 €

Silk PLAs normally produce impressive prints that are shiny and seemingly a bit translucent, giving them both the feel and look of being covered in silk. With this kind of filament, there’s no need to paint, as the natural appearance is already quite dazzling.

Parameter

Parameter

Parameter.

01

Gleaming

A silky touch and a long-lasting shiny glow with

fewer visible layer lines, leaving a soft touch

and an astonishing look to all your prints.

02

Premium Quality

3-years quality guarantee period, with high resilience and low

shrinkage rate which creates excellent results for every print.

03

Biodegradable

Made from natural corn and grain, which well-knowed

for their environmental friendly properties allowing the

Anycubic Silk PLA Filament to degrades naturally in nature.

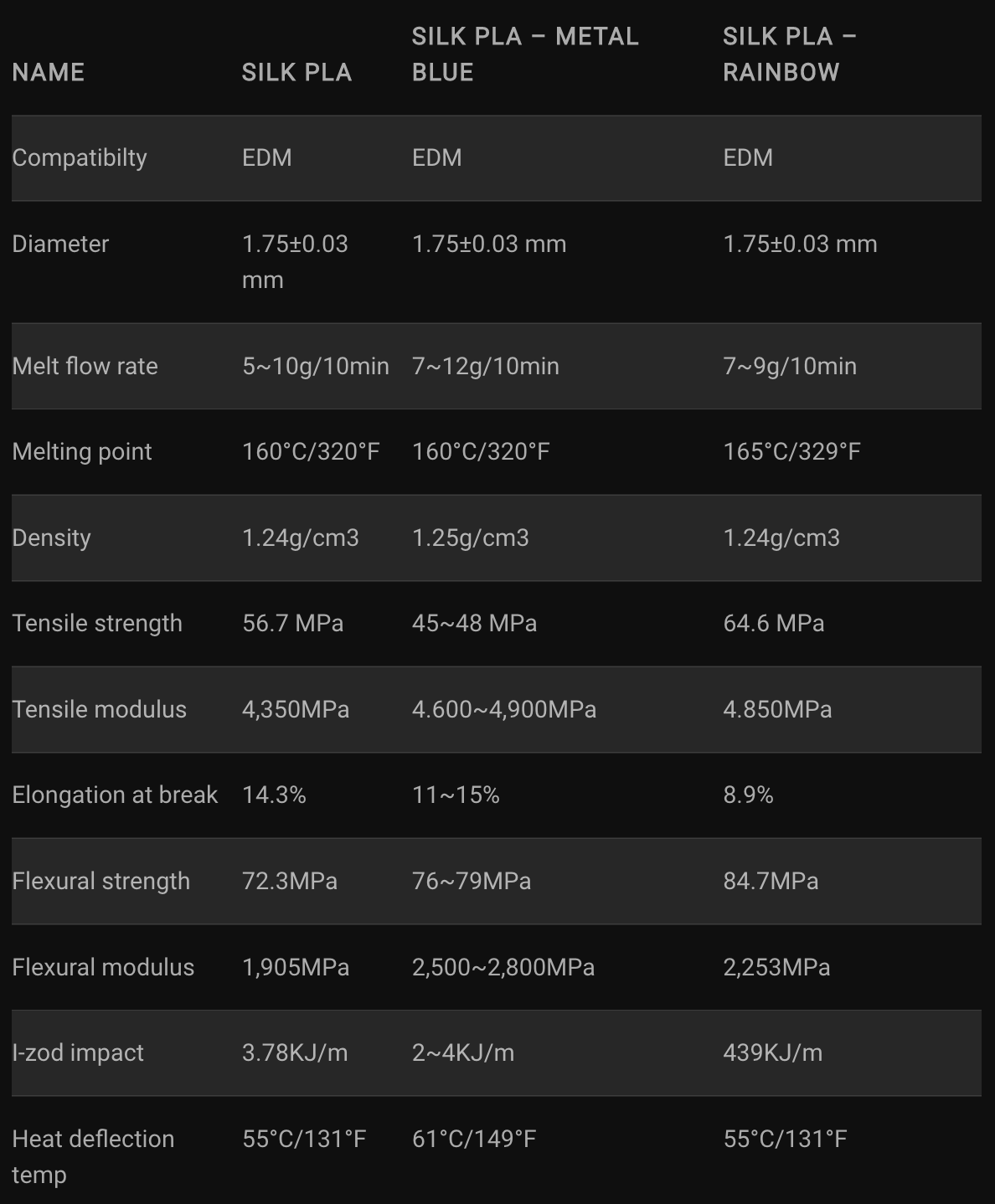

| Name | Silk PLA | Silk PLA – Metal Blue | Silk PLA – Rainbow |

|---|---|---|---|

| Compatibilty | EDM | EDM | EDM |

| Diameter | 1.75±0.03 mm | 1.75±0.03 mm | 1.75±0.03 mm |

| Melt flow rate | 5~10g/10min | 7~12g/10min | 7~9g/10min |

| Melting point | 160°C/320°F | 160°C/320°F | 165°C/329°F |

| Density | 1.24g/cm3 | 1.25g/cm3 | 1.24g/cm3 |

| Tensile strength | 56.7 MPa | 45~48 MPa | 64.6 MPa |

| Tensile modulus | 4,350MPa | 4.600~4,900MPa | 4.850MPa |

| Elongation at break | 14.3% | 11~15% | 8.9% |

| Flexural strength | 72.3MPa | 76~79MPa | 84.7MPa |

| Flexural modulus | 1,905MPa | 2,500~2,800MPa | 2,253MPa |

| I-zod impact | 3.78KJ/m | 2~4KJ/m | 439KJ/m |

| Heat deflection temp | 55°C/131°F | 61°C/149°F | 55°C/131°F |

Precautions

-

- Install the spool on the spool holder of a 3D printer, and preheat the nozzle.

- Cut the top of the filament into a spire shape, and thread it into the extruder and feeding tube.

- Manually push the filament through the feeding tube to the nozzle, until the filament melts through the nozzle.

-

When installing and replacing filaments, make sure to heat the print head (heated to above 230°C), otherwise the print head might get clogged.

Precautions.

-

- Install the spool on the spool holder of a 3D printer, and preheat the nozzle.

- Cut the top of the filament into a spire shape, and thread it into the extruder and feeding tube.

- Manually push the filament through the feeding tube to the nozzle, until the filament melts through the nozzle.

-

When installing and replacing filaments, make sure to heat the print head (heated to above 230°C), otherwise the print head might get clogged.

3D

You may also like.

You may also

like.